Get Quote

News

- Basic Farm Equipment MaintenanceFarm equipment requires good attention and maintenance. After all the money invested in collecting all this machinery, it's important to not let it go to waste. Some easy upkeep will help maintain your farm equipment in top, working order. One of the first problems that comes with not properly caring for your farm equipment would be rust. There are a number of ways to prevent it from occurring. After each use, every piece needs to be thoroughly cleaned. Most farmers use a good pressure washer to take care of any mud or dirt. It will need to be stored in a clean, dry space. If your farm does not already have a storage shed, it's time to consider buying one. On occasion, like you would do with your car, wax the machinery to maintain the paint job. There are also products created for the sole purpose of rust prevention. Besides rust, mechanical malfunctions can also be prevented or assessed. Take a walk around the machinery to make sure your tires; wheel bearings, and wheels look ready for use. The battery should be tested and inspected for corrosion to see if it's time for a replacement. Oil and coolant should also be inspected. If either is low, it's time for a change. Hose, fittings, and seals should be in their place and seem to be in good working condition. Look at the filters as well and replace as needed. After you've done a good walk around, have someone help you check if the signals, hazards, and lights are working. It's best to keep spare parts at your farm at all times. This way, you won't need to wait for long periods of time for an easy fix piece. Also, keep a log of all routine maintenance and work done to the machinery. A study done in the Midwest has shown that farmers who do this could lower their machinery repair costs by 25 percent. A way to maintain the machinery by yourself is to build your own workshop for the sole purpose of mechanical maintenance and care. As soon as farm equipment is done being used, wash it immediately. The best way to do so is with a pressure washer. While cleaning, you will need to avoid any seals that cover bearings. Any dirt or mud that sticks to the machine can cause corrosion. In addition, any left over crop residue could cause a fire next use. Before putting it back into storage, dry it thoroughly and then lubricate it. At times, farmers should take an oil sample to analyze if farm equipment is working in top and proper condition. Your local dealer could perform such an analysis for you or tell you where to go to get one. These tests can prove a base for normal condition, alert you to abnormal wear, or even tell you if you aren't changing the oil enough.

2015 10/20

- Things Need to Know When You buying Farm Equipment and MachineryOwning and operating a farm can be very expensive and time-consuming. You have so many things to keep track of such as your animals' feeding and care, as well as tending to your crops. Plus you have all the necessary repairs to your farm that have to be completed. When your to-do list is this big, the last thing you want to do is spend time comparing farm machinery. When you are looking for a quality company, keep in mind a few tips to save you time during your search. Longevity of Company How long has the company been in business? If they have been around for a while, you could assume that they provide excellent products and services. Plus, companies that stay in business for a long time generally will have plenty of referrals from current customers. If you are new to farm equipment or machinery, ask other farm owners for recommendations around your area. For example, if you are looking for Charlotte tractor parts, ask your neighbors if they can refer a local machinery company. Brand Diversity Does the company you are looking at have a diverse product base? Some people may like New Holland equipment and others might like Kubota. Find a dealer who has more than one brand to show you. Also, you may save time if you find a company that has both an agricultural division and a lawn and garden division. That way, you can find farm equipment for both instead of having to run all over town. Parts & Service What types of service does the company provide? Can you buy used or replacement parts for your equipment at the same place you buy the equipment? What is the turnaround on buying parts? Also, you may want to find a company that has more than just a few employees on staff. You may receive better customer service from a larger staff and they may have more knowledge to help you with your purchases. Also, look at the hours the company is open. Having regular hours plus being open on the weekend is helpful if you are busy running the farm during the week. Also, if you have a piece of equipment that needs repaired; it would be helpful if your farm machinery company offered pickup of that equipment at your farm. This will save you time and the headaches of trying to move ungainly equipment yourself. Financing Finding a company that will assist you in obtaining financing for your purchase will save you time. If you in the market for Charlotte riding lawn mowers, you may need financing for your purchase. If the company can help you find financing with a low-interest rate, that means more money in your pocket as well as the time you'll save trying to obtain your own financing. Also, see if the company offers trade-ins on your current equipment. You may be able to turn in your old stuff for money that you can put toward a new purchase.

2015 10/20

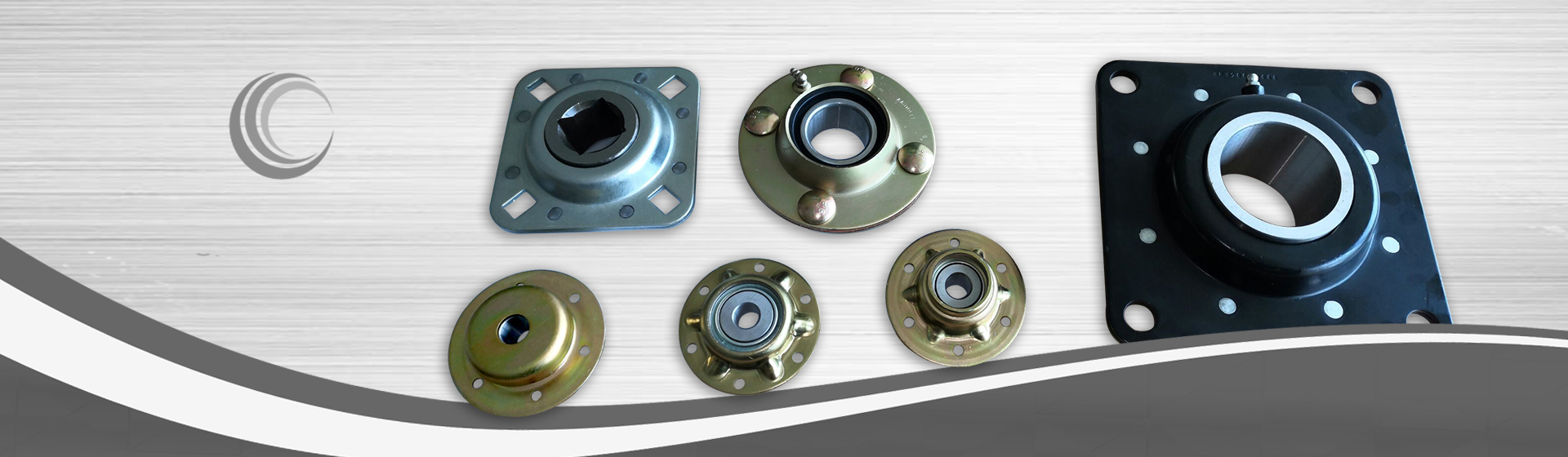

- The Importance of Bearings for the Agricultural SectorAs population keeps increasing, it is vital to enhance agricultural production to ensure regular availability of foodstuffs. Agriculture industry is under increasing pressure to meet the demands and meet them fast. Obviously, this industry can't be expected to come up to expectations unless its machines and tools are up to date and well maintained. With the rising demand for quick supplies of agricultural produce, machinery employed by agriculture industry needs to be more efficient and that can be possible only when there is further development in the design of machines to deliver more output. Like any other machinery, agriculture machinery too depends a lot on using bearings. Wikipedia defines bearing as device that allows constrained relative motion between two or more parts, typically rotation or linear movement. Bearings come in a large range of sizes and designs to suit specific applications and are classified as per their working principle and the direction of applied pressure that they can bear. Bearing are designed to reduce friction between two moving components of the same machine and thus play a vital role in making any machine efficient and keeping its operation smooth. There are many companies producing bearings for the agriculture industry. These manufacturers are helping the industry in their own way by offering bearings that keep agricultural machinery working efficiently. The precise bearing to be used for any machine depends on the design and functioning of that machine but an essential feature of any bearing is that it should provide perfect sealing while working under difficult conditions. For instance, tractors employ a number or bearings of different designs and specifications as the machine needs to work fast and accurately while encountering harsh and changing weather. Moreover, tractors are required to work under terrains of different types. In such cases, the bearings should be designed to prevent dirt from entering therein and avoid getting corroded due working environments. Machines employed by agricultural industry would most often use ball bearings, which again have different designs. Some of the more popular designs of ball bearings are bearings offering angular contact, ball bearing with deep groves and thrust bearings. Additionally, this industry also requires roller bearings, the two most frequently used designs of roller bearing are needle roller bearing and taper roller bearing. The key difference in the design of thee two bearings is that roller bearings provide linear contact instead of point to point contact. Thus roller bearings can bear more radial load but often operate at slower speeds so that heavier machines, which are frequently employed by agriculture industry, can use these efficiently. In case you are already employing agriculture machinery and looking for the perfect bearing for any of your machines, it is recommended to seek professional advice from a manufacturer or supplier of bearings.

2015 10/19

- China suffered a large area of summer drought in 2014, severe crop lossesSince July 2014, China's central, northern and northeastern sustained a wide range of hot weather, with an average rainfall of only 90MM, severe summer drought. Air temperature, dry, dry weather continued development, resulting in the occurrence of these areas more severe drought. Livestock draft drought caused difficulties in the agricultural sector caused by severe drought preliminary statistics area of six million hectares of crops affected by drought, wide extent of the drought in the history of heavy rare range. Pictured due to severe drought, causing pieces of corn crops difficult to grow, particles no income. upcoming harvest, farmers looking crops of corn, and tears. Drought to local farmers caused great economic losses.

2014 08/21

Email to this supplier